Business

NEW CHALLENGE TECHNOLOGY

Our Technology

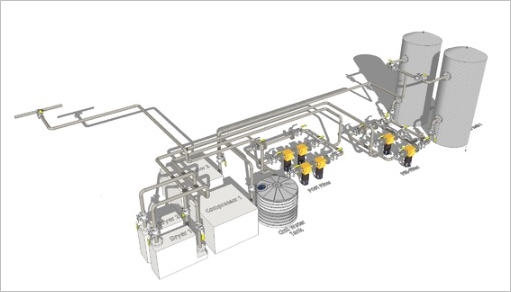

Utility System

We provide a cost reduction solution using the PCW system, which prevents overheating in the device, protects the equipment, and improves production yield through temperature control.

The multi-cooling system supplies coolant of a certain temperature to the PULLER among the coolant systems in the device. At the same time, it reduces the refrigeration load and operating costs by keeping the operation energy low.

-

1. Design and Preliminary Review

Preliminary review of customer request

Investigation of data and process target

Development of optimal plan through consultation

Establishment of overall process management plan

Design work

Layout of required quantity/production equipment

-

2. Procurement of Facility and Personnel

Investigation of/contract with core production facilities

Manufacturing structures for equipment installation

Procurement of required ingredients/materials/equipment

Securement of skilled specialists

-

3. Construction/Installation

Safety/manufacturing process/process management

Piping installation in case of utility pipes

Commencement of temporary work

Dispatch of skilled specialists

Schedule manager for management of manufacturing process

Flexible response through customized production

-

4. Test Run/Maintenance

Facility operation test

Check for missing/defective parts

Production quality test

Management of usage cycle

Improvement of facility/manufacturing process

Customer approval

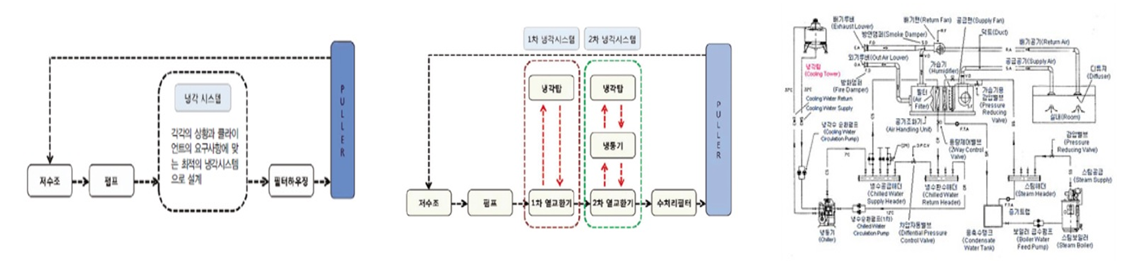

PCW System

We provide a cost reduction solution using the PCW system, which prevents overheating in the device, protects the equipment, and improves production yield through temperature control.

The multi-cooling system supplies cooling water of a certain temperature to the PULLER among the cooling water systems in the device. At the same time, it reduces the refrigeration load and operating costs by keeping the operation energy low.

-

-

1. Controlling the number of refrigerating machines

The initial investment cost and operation cost of unnecessarily operated refrigerating machines and cooling towers are reduced (about 15% reduction) by dividing the refrigeration capacity by the appropriate number of units.

-

2. Application of waste heat recovery system

The heating load during the winter season is reduced by inducing heat exchange between the room-temperature exhaust air from the production facility with fresh air from the outside, which is used for air conditioning.

-

3. Application of geothermal system

By implementing a geothermal system, it is possible to reduce the capacity of existing utility equipment and annual operating costs.

-

4. Application of the cooling tower arsenic acid suppression system

By applying a white lead reduction device to reduce the amount of white led and arsenic acid in the cooling tower, it is possible to reduce the amount of arsenic acid used annually by about 30% and the cost of industrial water.

-

5. Application of large temperature difference refrigerating machine

Reduction of initial investment and operation costs due to the reduction of cold-water flow rate by applying a large temperature difference refrigerating machine(about 30%)

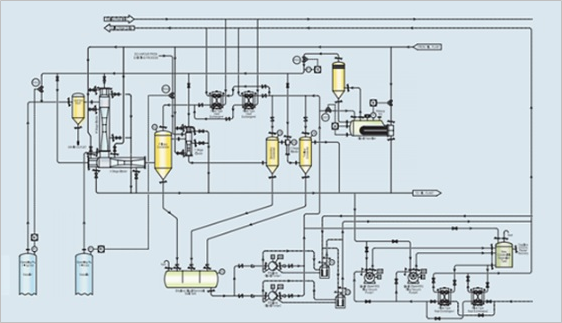

Types of Utility Systems

-

P.VC SYSTEM

The P.VC System is a VACUME (600-700mmAg) required for production facilities. It is an important system that should not be stopped or have a reduced vacuuming degree. It provides thorough management by maintaining a constant vacuuming degree and GAS conditions.

-

GAS SYSTEM

Various types of gas are used in the semiconductor manufacturing process, and the process requires ultra-high levels of purity and precision as well as professional construction and management capabilities. We provide a service that enables precise processing by removing and keeping O₂ and moisture below 1ppm.

-

CDA SYSTEM

The CDA SYSTEM is most often used with N₂ in production equipment as a system used for A.A.V (AUTO AIR VALVE) movement and transmission of all production equipment and other processes using air. We provide a service that enables automatic management with AIR. DI WATER SYSTEM

-

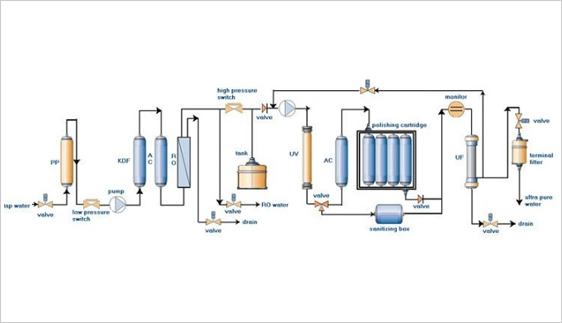

DI WATER SYSTEM

This system is mainly used for melting, etching, removing, and cleaning photo-registry. It reduces microorganisms, particles, organic matter, and level and offers a cost reduction effect with its simple maintenance.